The number of rear remotes that you need for the tractor could be confusing at first to determine, especially when you’re on your noob days. Wondering how many rear remotes exactly is quite normal in such a case.

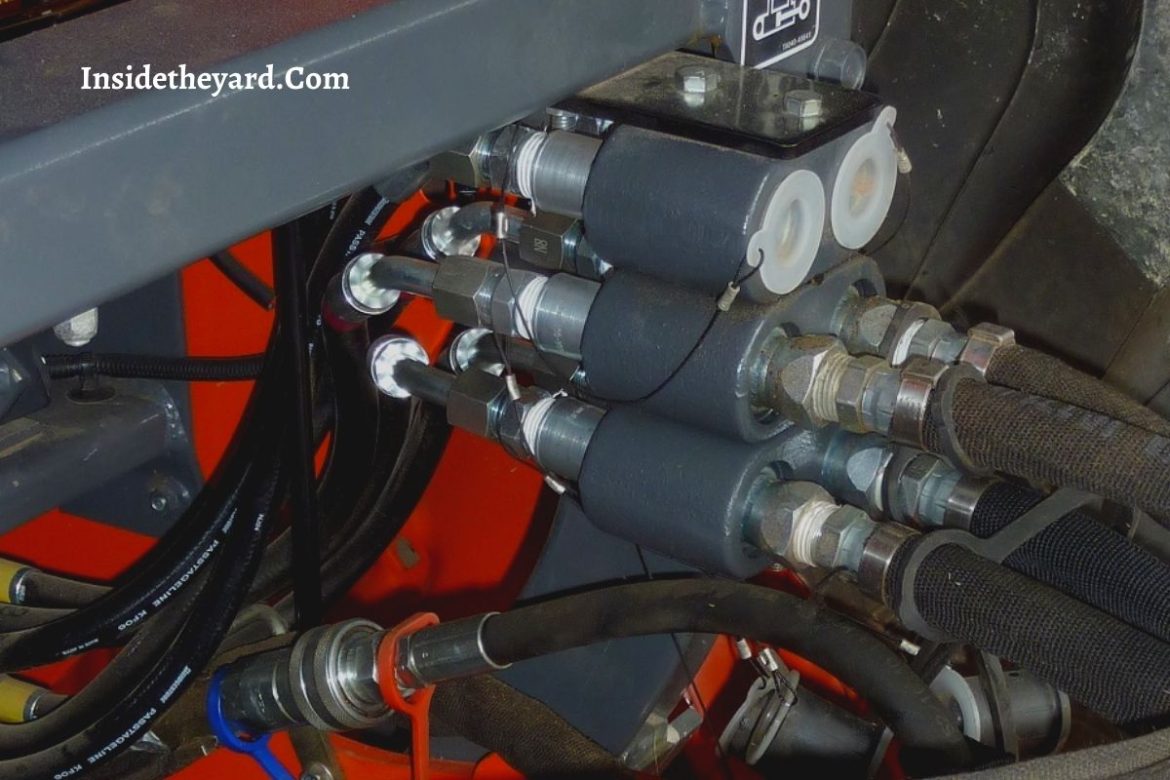

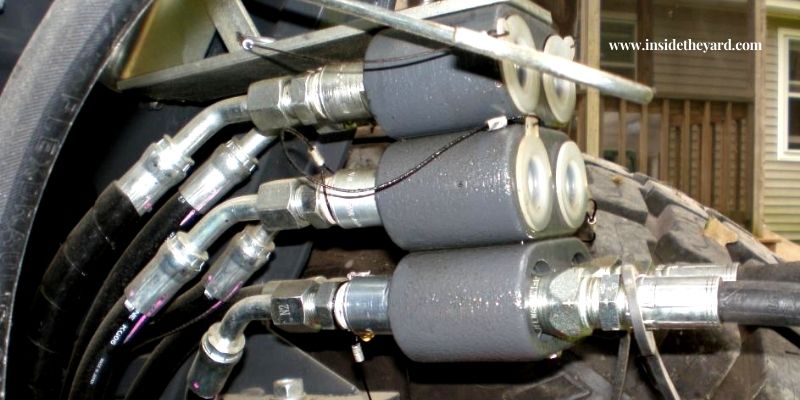

The rear remote is mainly a hydraulic implement addable connection point. These are super important as they provide a quick access area for using the hydraulic implements one would like to add. The hydraulic control valve is in charge of controlling the remotes.

Let’s help you today to determine the number of rear remotes that your tractor needs.

How Many Rear Remotes on The Tractor in Okay to Have?

To put the answer in one line, the number of rear remotes usually is between 1 to 4 sets. That doesn’t mean all tractors will go well with the number as much as you like. There’s more stuff you need to know before adding remotes to tractor.

Loader Tractor Rear Remotes

You can insert up to 3 rear remotes in the loader tractors as most have the option. But, if you go further, it might cause a real struggle.

To place the 3 rear remotes, you have to balance them by using 2 remotes on the top and insert tilt cylinders on the 3-point hitch.

We would suggest never to use the 3 rear remotes at the same time as they’ll restrict you from shifting the top link and side links hydraulically.

For Your Information: If your tractor contains 1 cylinder, then be sure to add at least 1 rear remote. Each cylinder that works at any given time will need a set of rear remotes.

Compact Tractor Rear Remotes

If you are thinking ‘how many rear remotes do I need in my compact tractor’, the answer would be no more than 3 rear remotes.

FYI, the compact tractors do not have stock with remotes from the manufacturer due to the high cost. But some of them do contain the rear remotes like the legendary Kubota L3130.

These are placed in the tractor in a special arrangement. The one remote contains 2 ports (which is normal) on a top link while the second remote fit on the front of the FEL (Front End Loader).

The 2nd one help to rotate the tree shear to work fine when using on the ground. Then, the last rear remote is inserted on the front line of the FEL (similar to the second remote). This helps open or close the tree shear or similar work.

AG Tractor Rear Remotes

Most AG (Agricultural) tractors come with 2 rear remotes. However, the number of remote can change depending on the use or purpose.

If it’s about agricultural works, then 1 rear remote would be ideal to dump the baler or work with other implements.

Do You Know: A rear remote needs 1 valve spool that has 2 work ports or connectors to attach to the cylinder. Based on the flow direction, the work ports can be a cylinder inlet or outlet.

More About Tractor Rear Remotes

At this point, you could be wondering what are rear remotes on a tractor used for apart from playing the role of a connection point. Not much. Rear remotes are mainly responsible for allowing additional hydraulic cylinders through the quick connections one finds on the back side of a tractor.

If you try to have a look at the rear of the tractor, you’ll find a rear hydraulic outlet. And most at this point simply guess all are quite the same.

However, that’s not the case with the tractor remote hydraulic valve. There is actually a wide range of styles that these valves come in. And mechanisms wise also they are different.

Even the tractor remote hydraulics systems associated are varying in oil pumping through valves. Depending on the implement type, the difference can be crucial to know about.

Spring Center Valve Is Mechanically Simplest, Least in Cost Type

The cheapest type of the spring center valve. And you will find a basic lever with this type. It will require pressing back or forward to pop in the center. The same thing happens if you let go of the lever Mechanism-wise, these are the simplest type to exist and that’s why the price is so less usually.

In fact, the price is almost half of what the deluxe counterparts charge. Now keep in mind there are some application limitations with spring center valves. And this happens due to a lack of hold open function or float function.

To lift the tractor wheels, you won’t be able to float the spring center. Again, for any constant flow, there’s no way to lock it open.

Rear Remote Usually Have 2 Types of Detents

Float detent and self-canceling detent. The first type is where you require pushing the valve forward. As you do that, a pop will be felt and that shall travel on top of the detent ball so that the valve can hold in that forward position.

Once you pop into this detent, the float position will be activated. And then the oil from one side to the next starts free following. There’s no pressure flowing through it.

This type is mainly used for transporting wheels. You can easily throw it in a float position when dealing with a transport system on the disc. And it will drop to the ground allowing the wheels to freely move.

This is also used often on top and tilt kits by the way. you should consider float detents if you require self-moving of the top cylinder without any tractor input.

Then there’s the self-canceling detent. Now, this type gives the user the flexibility of taking the valve and pushing over the detent.

The valve will move to a place where the oil will begin to a dead end. And then it shall pop the thing right back to neutral mode.

With the self-canceling position working for the transport wheel, you can expect the wheels to lift up until the cylinder extends and the valve cancels the oil flow. Whenever that happens the valve will go back to the neutral position.

And that just makes it understandable why a self-canceling valve is almost essential for certain applications.

Especially where you don’t want the oil to go through a bypass or begin a dead end. If that happens, then heat generation, as well as other issues, arises in the hydraulic system.

That’s How Mechanically the Valve Works!

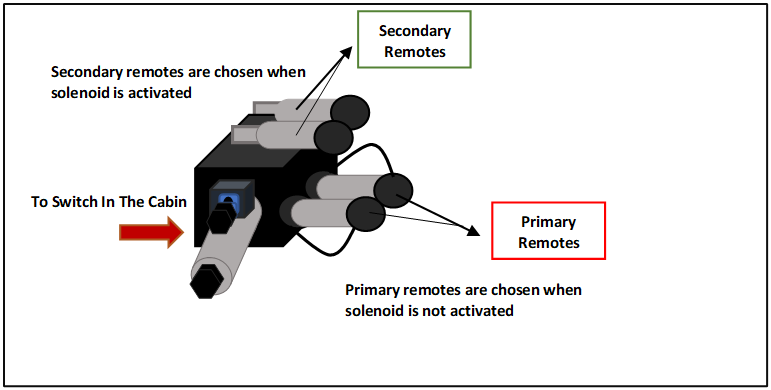

Now oil pumping into the valve stacks is operations are done but two different systems. And these are called the open or closed center.

With an open center, a simple gear pump is in charge of pumping oil running. Here the oil travels through a route that is least resistant.

So, with multiple functions available at a similar time frame, the oil will travel exactly where flowing out is easiest. And in a complex operation, this can lead to unpredictable results. Most tractors that are beneath the 150 horsepower mark use open center systems.

The exact opposite mechanism is a closed center system. The close center pumps are actually variable displacement types. And they have the flexibility of dialing demand up or down. It will depend on what the rear remotes need at the point.

For example, if there’s a need for constant flow or pressure out of a specific outlet, then the close center systems can easily provide for that.

There are lots of program abilities that these have when done with electronic rear remotes. And that means they can conduct specific timing operations as well as have automatic headland functions.

Adding Rear Remotes to Tractor That Is Small in Size – Definitely Worth It!

Many consider adding hydraulic remotes to a tractor that is an averagely small size. And in that case, wondering if it’s even worth it or not is clearly a valid confusion.

Such confusion comes from the fact that small compact tractors often don’t have much room on the back. However, users could have desires of adding implements such as a TNT kit for box blades and so on.

If there’s room for mounting valve stack and couplers, then it has pretty solid worth. However, the real question is how many rear remotes you’re planning to add for a tractor of such size.

In some cases, you also need to consider whether there’s a need for 3PH removal for running a backhoe.

- Adding 3 will give you a 3-spool valve setup. And one valve being float while one detent shall make a great combination. Here’s what doing would be most useful:

- You can use the existing backhoe hoses and try running a supply to the new remote valve.

- Of course, it requires a PB plug which will have the backhoe hoses’ return line.

- A tee into the tractor’s tank line as well as a return-focused 3rd line is necessary.

- Finally, you can mount the 3 remote couplers just the way you prefer.

Also, consider plugging the backhoe into a detent included remote valve whenever there’s a need to mount the backhoe.

However, if you must remove the 3PH for using a backhoe, 2 remotes need to be chosen. All this costs a little less than 1000 dollars with a little effort from your side. Also, small tractors do excellent with a hydro tap.

You May Like This Video Too!

Wrapping Up

And that’s an insight on how many rear remotes you really need as well as some deep explanation regarding the main protagonist, rear remotes.

Hope you will be able to use this information for your purpose well.

On that note, we’ll be asking for your leave today! We’ll be right back with another important stuff soon!

You Can Also Read:

- John Deere 180 Transmission Problems And Solutions

- A Complete Guide for Husqvarna Lawn Tractor Hydrostatic Transmission Problems

- Fix Cub Cadet Hydrostatic Transmission Problems Quickly with 5 Amazing Maintenance Tips

- Craftsman Lawn Tractor Transmission Problems

- John Deere Hydrostatic Transmission Problems

Was it helpful?

Enamored with the world of golf Jack pursued a degree in Golf Course Management at THE Ohio State University. This career path allowed him to work on some of the highest profile golf courses in the country! Due to the pandemic, Jack began Inside The Yard as a side hustle that quickly became his main hustle. Since starting the company, Jack has relocated to a homestead in Central Arkansas where he and his wife raise cattle and two little girls.